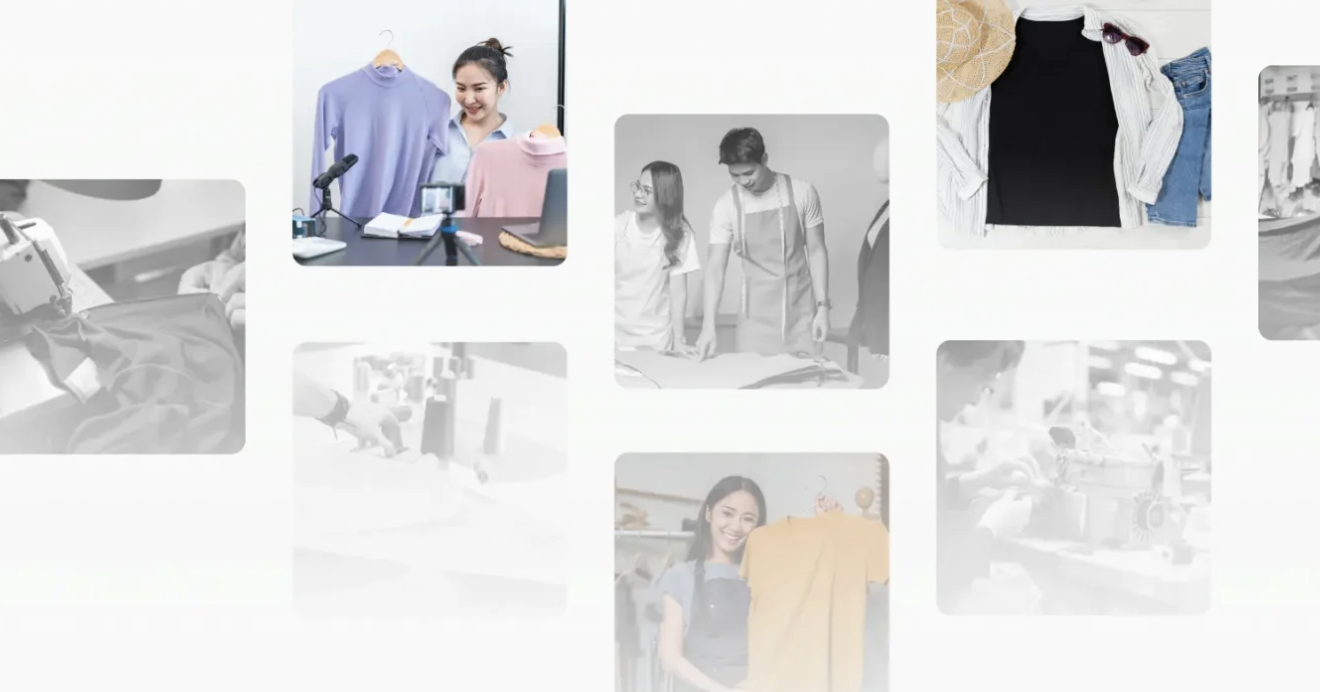

Garment manufacturing is a vital and intricate industry that plays a significant role in the global economy. It encompasses a range of processes, from designing and selecting materials to producing and distributing ready-to-wear garments. Behind each piece of clothing is a detailed supply chain involving several stages and technologies. This article delves into the workings of garment manufacturing, the challenges it faces, and the innovations that continue to shape the industry.

Contents

The Garment Manufacturing Process

The garment manufacturing process can be broken down into several key stages:

- Design and Product Development The process starts with design, where fashion designers or design teams create the clothing’s style and aesthetics. They choose fabrics, colors, and patterns, taking into account trends, functionality, and customer preferences. After the initial design is made, prototypes are created to test the product’s fit, appearance, and comfort. Once approved, the design goes into production planning.

- Pattern Making and Grading The next step is pattern making, where the garment’s design is translated into templates or blueprints that guide the cutting of fabric. These patterns are usually made for various sizes, requiring a process called grading to adjust the original pattern to fit different body measurements. Accurate grading ensures consistency in size across mass production.

- Fabric Selection and Sourcing Choosing the right fabric is crucial, as it affects the garment’s durability, comfort, and overall look. Manufacturers source fabrics from local or international suppliers, with factors such as cost, availability, sustainability, and fashion trends influencing decisions. Natural fibers like cotton and wool, synthetic materials like polyester, or blends of both are commonly used.

- Cutting Once the fabric is selected, it is cut into the required shapes and sizes based on the patterns. Automated cutting machines are often used in large-scale operations to improve efficiency and reduce waste, though manual cutting is still common in smaller or specialized factories.

- Sewing After the pieces are cut, they are sewn together to form the final product. This step requires skilled labor and involves using sewing machines, either manually operated or automated. Different types of stitching are used depending on the garment’s style and fabric, and quality control is crucial to ensure seams are strong and neat.

- Finishing Finishing involves several tasks that prepare the garment for retail, including adding buttons, zippers, labels, or other details. Pressing and ironing are also done to improve the appearance of the clothing. Sometimes, treatments like washing or dyeing are added to achieve a particular texture or look.

- Quality Control and Packaging Before garments are shipped, they undergo rigorous quality control checks to ensure they meet the required standards. Defective items are either reworked or discarded. Once approved, the clothing is packaged and labeled for distribution.

- Distribution The final step is distributing the garments to retail stores, wholesalers, or directly to consumers through online platforms. Logistics play a crucial role in ensuring timely delivery and minimizing costs.

Read more about garment manufacture and consult your needs with OL Garments

Challenges in Garment Manufacturing

Garment manufacturing faces several challenges, particularly in today’s fast-paced, globalized market.

- Sustainability and Environmental Impact The fashion industry is often criticized for its negative environmental impact. The use of synthetic fabrics, excessive water consumption, chemical dyes, and waste production are some of the main environmental concerns. Fast fashion, in particular, encourages high production volumes and rapid consumption, leading to waste and pollution.

- Labor Issues Many garment factories are located in developing countries where labor is cheap, but workers often face poor working conditions, long hours, and low wages. Ethical concerns over workers’ rights and safety have led to increased scrutiny of supply chains, pushing brands to adopt more transparent and responsible practices.

- Technological Adaptation While technology has significantly improved manufacturing efficiency, many traditional garment factories struggle to adopt modern, automated systems due to high costs. Smaller manufacturers, in particular, face challenges in competing with larger companies that invest in advanced machinery.

- Supply Chain Disruptions Global supply chains are vulnerable to disruptions from political instability, natural disasters, and economic fluctuations. The COVID-19 pandemic highlighted the fragility of these networks, causing delays in raw material sourcing, production, and distribution.

Innovations Shaping the Future of Garment Manufacturing

Despite the challenges, the garment industry is evolving with several innovations:

- Sustainable Fabrics and Practices Manufacturers are increasingly adopting sustainable practices, such as using organic or recycled materials, reducing water consumption, and minimizing waste. Brands are also exploring biodegradable fabrics and eco-friendly dyes to lessen environmental harm.

- Automation and Smart Manufacturing Automation is transforming garment manufacturing by streamlining processes such as cutting, sewing, and quality control. Technologies like robotic sewing machines, 3D knitting, and AI-driven design tools are making production faster, more efficient, and less reliant on manual labor.

- Customization and On-Demand Production On-demand manufacturing is gaining traction as consumers seek more personalized clothing options. Technologies like 3D printing and digital pattern making allow for smaller, customized production runs, reducing overproduction and excess inventory.

- Circular Fashion The concept of circular fashion aims to extend the lifecycle of garments through recycling, upcycling, and reusing materials. This approach reduces waste and encourages a more sustainable consumption model.

Conclusion

Garment manufacturing is an essential industry that bridges fashion creativity with practical production processes. While it faces significant challenges related to sustainability, labor, and technological adaptation, innovations in fabric technology, automation, and responsible sourcing are reshaping the future of the industry. As consumers become more conscious of the environmental and social impacts of their clothing, the garment manufacturing sector is likely to continue evolving towards more sustainable and ethical practices.

![Kumpulan ROM Xiaomi Redmi 3 : Stabil China / Developer / Distributor [UPDATE]](https://www.teknosid.com/wp-content/uploads/2016/05/xiaomi-redmi-3-copy.jpg-100x70.jpg)